Ship ahoy at Regensburg soil treatment center: 1,650 t of soil loaded in nine hours

- Bauer Resources recently carried out the transshipment of soil material at the soil treatment center using waterways.

- The amount loaded corresponds to approximately 63 truck loads.

- Less CO2 and less traffic on the road – transport by barge offers several advantages.

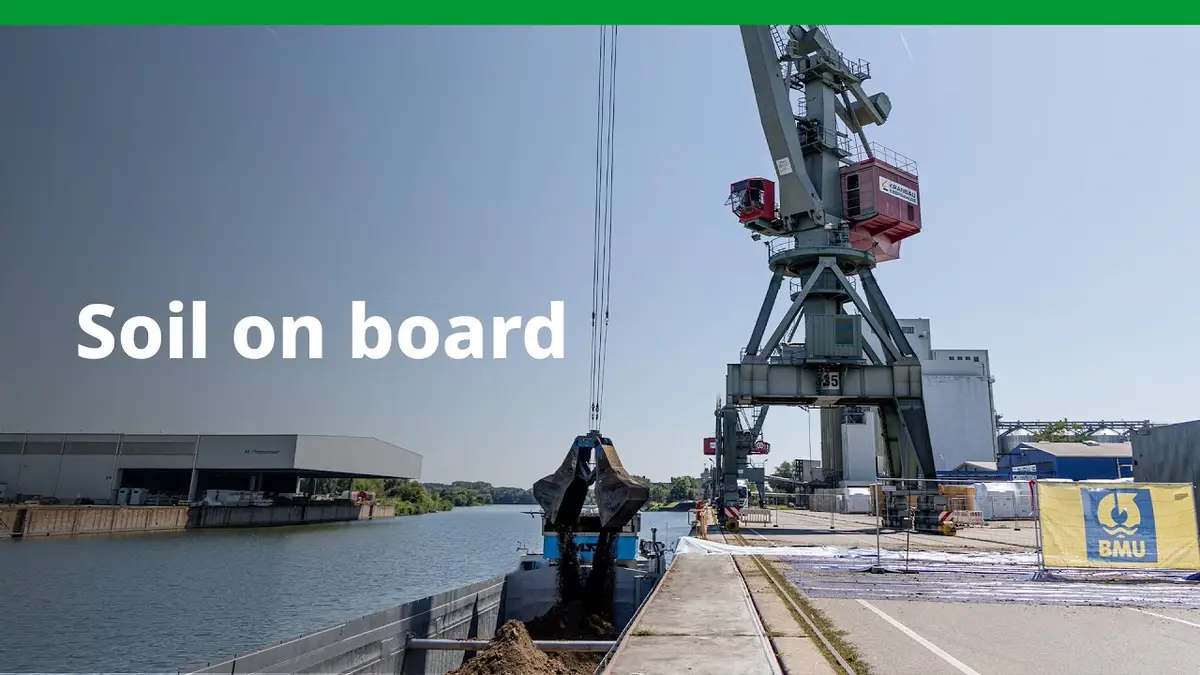

Regensburg, Germany – Clack! The steel grab of the harbor crane lowers through the open roof of the hall, grabs approx. 5 t of soil and lifts it effortlessly into the air. With a controlled swivel movement, the cargo is emptied onto the waiting ship. Then, the grab returns to its starting position. This process is repeated over and over again until the ship is fully loaded. The venue: the Regensburg soil treatment center of BAUER Resources GmbH. Recently, a ship was successfully loaded there in collaboration with Rhenus, in the middle of bayernhafen Regensburg – another step forward, with many advantages and challenges.

Abracadabra, open the roof!

A total of 1,650 t of soil from various Bavarian construction projects was transferred to a barge. What initially sounds like a complex process turned out to be surprisingly uncomplicated thanks to the sliding roof on the port basin side of the site. "This special functionality made it possible for the soil to be transferred directly onto the ship," explains Helen Wagner, Head of the soil treatment center at BAUER Resources GmbH, and adds: "Nevertheless, loading took about nine hours." And where will the soil be taken now? To a disposal facility located outside Bavaria. Due to the limited disposal capacities for certain waste categories, landfill facilities outside the federal state are used for some pollution classes.

More environmental protection, less CO2

At bayernhafen Regensburg, Bauer Resources demonstrates that sustainability is not just a buzzword, but an established practice. This is because soil transport by ship offers clear advantages over road transport: Transshipment on waterways significantly relieves roads and motorways, reduces congestion and minimizes wear and tear on traffic routes. From a climate protection perspective, the advantage is even greater: Compared to a forty-ton truck, a barge consumes about a third less energy. This significantly reduces greenhouse gas emissions and noticeably lowers air pollution.

The effort is worth it

In order to be allowed to load mineral waste onto the ship, a permit is required in accordance with the Federal Immission Control Act. "Even during the design and approval phase, we deliberately decided on a location with a port connection, as flexibility is becoming increasingly important for transport operations," emphasizes Helen Wagner. Even though ship loading entails some challenges – such as the coordination with the shipping company, the scheduling of loading and unloading times, as well as the ordering of port logistics and the deployment of additional personnel – the effort pays off.

Video

Press Images

Download

Your Contact

Specialized press Resources, Redevelopment, Environment